BMEL-Project: EmissionPredictor

BMEL-Project: EmissionPredictor – Prediction and reduction of pollutant emissions in biomass combustion using intelligent controls

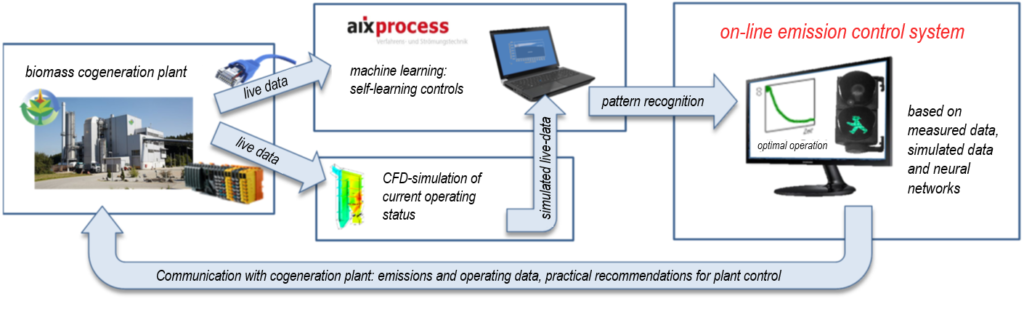

The project EmissionPredictor develops an intelligent on-line operation assistance system on the base of the numerical simulation results describing the formation of gaseous emissions.

Support Code: 22040318

Term: 04/01/2019 – 03/31/2022

FNR Fachagentur Nachwachsende Rohstoffe e.V.

Bundesministerium für Ernährung und Landwirtschaft

For future increased utilization of biomass residual fractions, the real-time optimization of the control engineering of the combustion is necessary. Fluctuating fuel quality concerning the composition and size of the pieces directly influence the formation of nitrogen oxide as well as intermediate products like carbon monoxide. Large biomass potentials cannot be used due to the resulting exceedance of emission limits.

Aim of the project “EmissionPredictor” is an on-line emission control system based on simulations that describe the formation of gaseous emissions in a biomass furnace. For the validation of the simulation results, data from the biomass cogeneration plant Altenstadt and experimental results are used. Fluctuations of fuel quality during operation of the biomass combustion in Altenstadt are measured by optical sensors. The collected data combined with the simulation results lead to a self-learning on-line emission control system that will make practical recommendations for the plant control.

Contact:

Department of Chemical and Biological EngineeringJohannes Lukas, M. Sc.

Lehrstuhl für Energieverfahrenstechnik