BMEL-project: FlexBiomethane

BMEL-project: FlexBiomethane – Direct catalytic methanation for improved flexibilization of small- and mid-scale biogas plants

Support code: 22035318

Term: 01.01.2020 – 31.12.2022

FNR (Fachagentur Nachwachsende Rohstoffe)

Förderprogramm „Nachwachsende Rohstoffe“

Förderschwerpunkt „Entwicklung innovativer Konversionsverfahren auf der Basis nachwachsender Rohstoffe“

Federal Ministry of Food and Agriculture

Technische Hochschule Ingolstadt (THI)

regineering GmbH

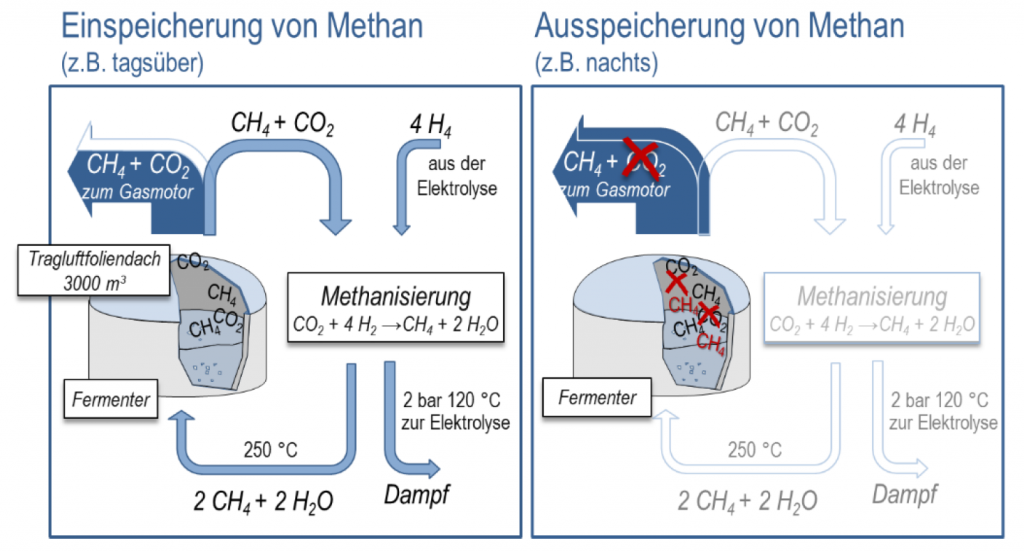

The flexibilization of biogas plants is one key objectives of last year’s EEG amendments. The aim is to throttle electricity production in line with demand (for example during the day) and to shift electricity production to cover electricity demand peaks (for example during night). The “power-to-gas” concept uses the biogas or wastewater treatment plant only as CO2 source for methanation and is therefore limited to large biomethane plants. However, the process chain would be significantly simplified if the CO2 did not have to be completely separated for methanation and could be directly catalytically converted and temporarily stored in the existing gas storage volume of the fermenters. In the proposed concept, biogas is therefore continuously extracted from the digester. The CO2 content is directly catalytically converted into methane and fed back into the digester. This continuously increases the proportion of methane in the gas storage volume of the fermenter and significantly simplifies the process chain and waste heat utilization. Since there is no need to feed gas into the grid, the effort and costs are substantially reduced compared to established concepts.

Finally, the objectives of this project can be summarized as

- integrated plant concepts for small- and mid-scale biogas plants

- development of a suitable methanation reactor concept with production of saturated steam

- direct heating of the fermenter with steam and hot product gas

- long-term testing of the methanation reactor with real biogas

The Chair of Process Engineering (EVT) is in charge of the development, experimental characterization and demonstration of a suitable and modified heat pipe cooled methanation reactor.

Ansprechpartner:

Department of Chemical and Biological EngineeringDr.-Ing. Peter Treiber

Lehrstuhl für Energieverfahrenstechnik