Renewable hydrogen in the natural gas grid

BHC-project: Regenerative hydrogen in the natural gas network

The BHC (Bavarian Hydrogen Center) Is a cooperation project of the FAU with other research facilities. In the research project, the scientists involved are looking for opportunities for the extraction and use of hydrogen from exclusively regenerative sources. In addition, the researchers want to promote the systematic expansion of chemical energy storage using hydrogen.

![]()

Bayerische Staatsregierung

- Friedrich-Alexander-Universität Erlangen-Nürnberg

LS für Chemische Reaktionstechnik (Prof. Wasserscheid, Prof. Schwieger)

LS für Thermische Verfahrenstechnik (Prof. Arlt, Prof. Kaspereit)

LS für Technische Thermodynamik (Prof. Wensing)

LS für Prozessmaschinen und Anlagentechnik (Prof. Schlücker)

Erlangen Catalysis Resource Center (Prof. Hartmann)

- Technische Universität München

LS für Thermodynamik (Prof. Sattelmayer)

- Universität Bayreuth

Zentrum für Energietechnik (ZET) (Prof. Brüggemann)

- Hochschule Amberg-Weiden

One possible approach to storing excess current from wind energy and photovoltaics is the catalytic low-temperature reforming of natural gas by exploiting the storage capacities of the existing natural gas network. By the endothermic reaction to hydrogen, energy can be temporarily stored in the form of reaction enthalpy to compensate for fluctuations in the production of electricity.

Reaction equations of the main component contained in natural gas Methane:

| CH4 + H2O ⇄ 3 H2 + CO | ΔHR= +206 kJ/mol |

| CO + H2O ⇄ H2 + CO2 | ΔHR= -41 kJ/mol |

| BRG: CH4 + 2 H2O ⇄ 4 H2 + CO2 | ΔHR= +165 kJ/mol |

As the equation system shows, 165 kJ per mole of methane can thus be stored. This corresponds to an energetic upgrading of the product gas of 20-25% depending on the reaction conditions.

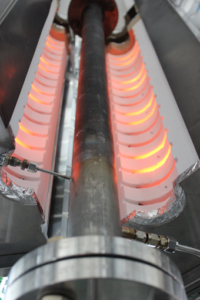

Katharina Großmann in the operation of the Monotube-Steam Reformers

Contact Person:

Dr.-Ing. Peter Treiber

Department of Chemical and Biological Engineering

Lehrstuhl für Energieverfahrenstechnik

- Phone number: 09115302-99035

- Email: peter.treiber@fau.de