BMWi-project: FlexSOFC

Improved utilisation of intermittent low calorific gases in SOFCs (FlexSOFC)

The BMWi-founded project aims at the scientific question if the interconnection of biomass gasifiers and SOFCs is possible.

Support Code: 03KB112

Term: 01.08.2016 – 31.07.2019

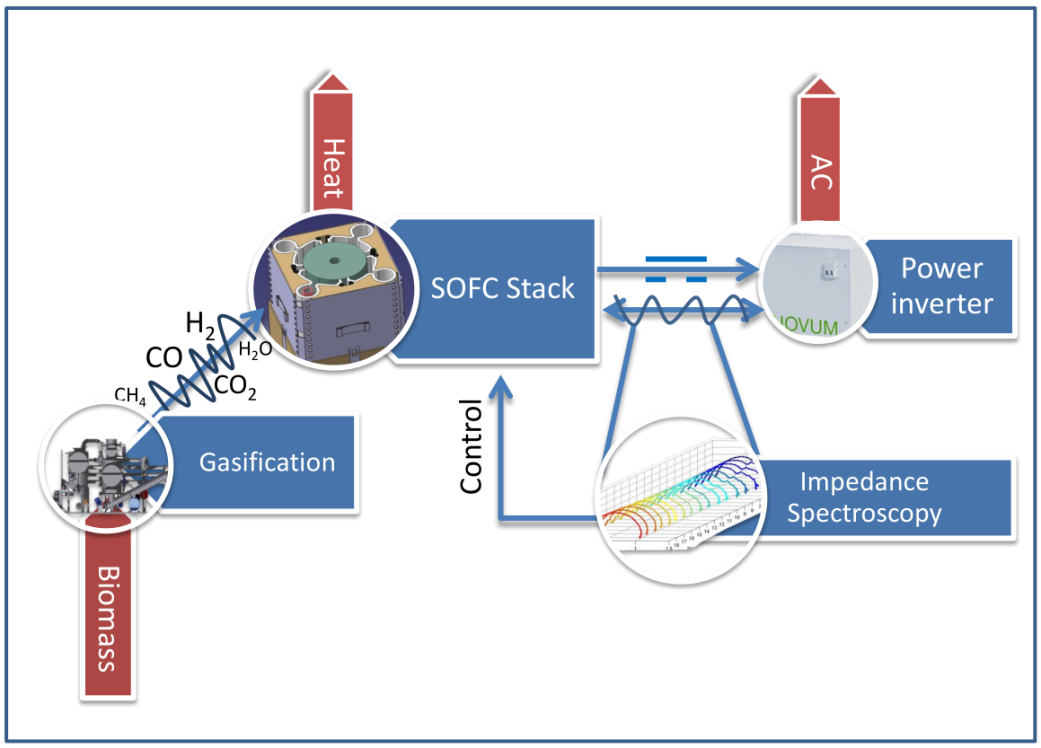

Integrating solid oxide fuel cells (SOFC) with biomass gasification is an innovative way to decentralise the cogeneration of heat and power. The electrochemical conversion of producer gas in a SOFC is electrically much more efficient than the combustion in a gas engine. Additionally, the high temperatures at the nickel anode facilitate reforming of tars, which would usually acquire extensive gas cleaning.

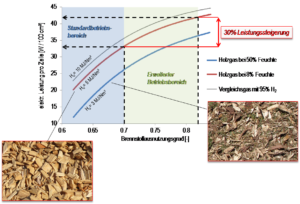

However, the fluctuating nature of biomass produced gas is considered as a serious problem for the operation of the fuel cell. Due to lacking fuel quality the nickel anode might be exposed to conditions which enable the oxidation of metallic nickel to NiO. The reoxidation has to be avoided because it will degrade the cell permanently. Hence, previous wood gas experiments were operated with very limited fuel utilisation (30 %). Realising higher fuel utilisation is beneficial in terms of power density and consequently economics.

Since August 16 the research project FlexSOFC is investigating possibilities to identify critical cell conditions during the operation. Therefore, the cooperating partner NOVUM engineering GmbH designs a power inverter, which is able to deliver real-time impedance data. In order to describe the current cell condition, characteristic values are derived from electrochemical impedance spectroscopy.

Within the project the existing 1 kW SOFC stack at the Chair of Energy Process Engineering is adapted to the utilisation with producer gas. Electrochemical impedance spectroscopy will be integrated in the control system to encounter critical cell conditions.

Possible improvement of performance for the use of low calorific gases:

Contact Person:

Federica Torrigino, M. Sc.

Department of Chemical and Biological Engineering

Lehrstuhl für Energieverfahrenstechnik

- Phone number: 09115302-99403

- Email: federica.torrigino@fau.de