BMWi-project: Power-to-Biogas

BMWi-project Power-to-Biogas:  Increasing the flexibility of biogas plants using catalytic methanation and machine learning

Increasing the flexibility of biogas plants using catalytic methanation and machine learning

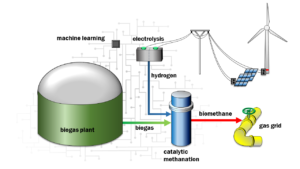

The Power-to-Biogas project investigates the technical and economical optimization of catalytic methanation with regard to biogas upgrading. In order to ensure optimal operation, the methanation process incorporates machine learning methods for autonomous plant control.

Support code: 03KB165A

Term: October 2019 – September 2022

Funding program

Biomass energy use

The project addresses the increase in flexibility of biogas plants and the on-demand production of electricity based on biomass. This approach involves catalytic methanation in order to convert carbon dioxide, a major component of biogas, into methane using hydrogen. The hydrogen production is connected to a power supply. Therefore, the overall process enables the conversion of surplus electrical energy into the chemical energy carrier, methane. As a result, the methane yield increases and the specific emissions of biogas plants are considerably reduced. The process itself can be enhanced using machine learning methods, which utilize data from individual biogas plants and the electricity market to adapt and optimize methanation from an economic point of view.

The project objectives include the integration of dynamic methanation of biogas into a commercial biomethane plant and its test operation. The cost-effectiveness of the overall process shall be optimized by virtue of autonomous plant control and machine learning methods.

Contact:

Department of Chemical and Biological EngineeringSimon Markthaler, M. Sc.

Lehrstuhl für Energieverfahrenstechnik