CO2freeSNG 2.0

EU Project CO2freeSNG2.0 – Advanced Substitute Natural Gas from Coal with Internal Sequestration of CO2

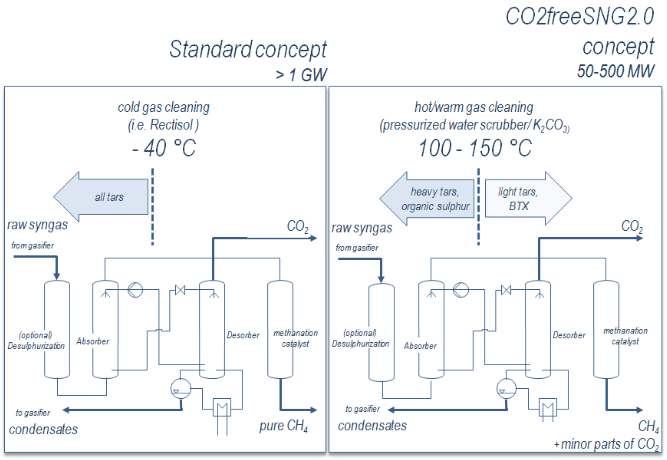

The follow-up project to CO2freeSNG targets at the complete SNG process chain demonstration of an innovative process technology with European coal and lignites. The new process comprises a substantially simplified gas cleaning based on carbonate scrubbing. It allows to simultaneously remove CO2, sulphur and tar components by means of a single pressurised water/ carbonate scrubbing system and will substantially increase the process efficiency in comparison to state-of-the-art systems.

Support Code: RFCR-CT-2013-00008

Term: 01.07.2013 – 30.06.2016

The proposed project shall continue a previous RFCS project (i.e. CO2freeSNG) which had set its focus on the conversion of coal into substitute natural gas (SNG) by means of methanation of coal derived syngas in the 50 – 500 MW range.

The main advantages of such coal-to-SNG systems are their unique ability for backing up the increasing share of fluctuating renewable energies (i.e. wind, pv) in the European electricity grid. Storing continuously energy from coal as Substitute Natural Gas (SNG) in the existing gas grid infrastructure in order to provide this energy on demand to flexible gas turbines and highly efficient combined cycles combines ideally with wind and photovoltaics.

The state-of-the-art for Coal-to-SNG systems comprises large scale systems with entrained flow or oxygen-blown gasifiers including an extensive cleaning of the syngas. Cold gas cleaning by means of the Rectisol process implies scrubbing of the syngas at -40ºC to -70ºC with significant efficiency losses and an extraordinary high technical effort. However, grid injection requires usually medium-scale systems in order to use existing grid infrastructure due to usually locally limited gas injection capacities. The CO2freeSNG2.0 project targets at an innovative and medium-scale coal-to-SNG system with a substantially simplified gas cleaning at elevated temperatures.

The previous CO2freeSNG project successfully proved the feasibility of such medium-scale systems in combination with gas cleaning and carbonate based scrubber systems at elevated pressures and temperatures. The proposed continuation of the former project shall focus on a pre-pilot scale demonstration (150 kW) of the complete process chain in order to improve the technological basis for a demonstration at a commercial scale

Contact Person:

Dr.-Ing. Peter Treiber

Department of Chemical and Biological Engineering

Lehrstuhl für Energieverfahrenstechnik

- Phone number: 09115302-99035

- Email: peter.treiber@fau.de