EU-Project CarbonNeutralLNG

EU-Project CarbonNeutralLNG – Truly Carbon Neutral electricity enhanced Synthesis of Liquefied Natural Gas (LNG) from biomass

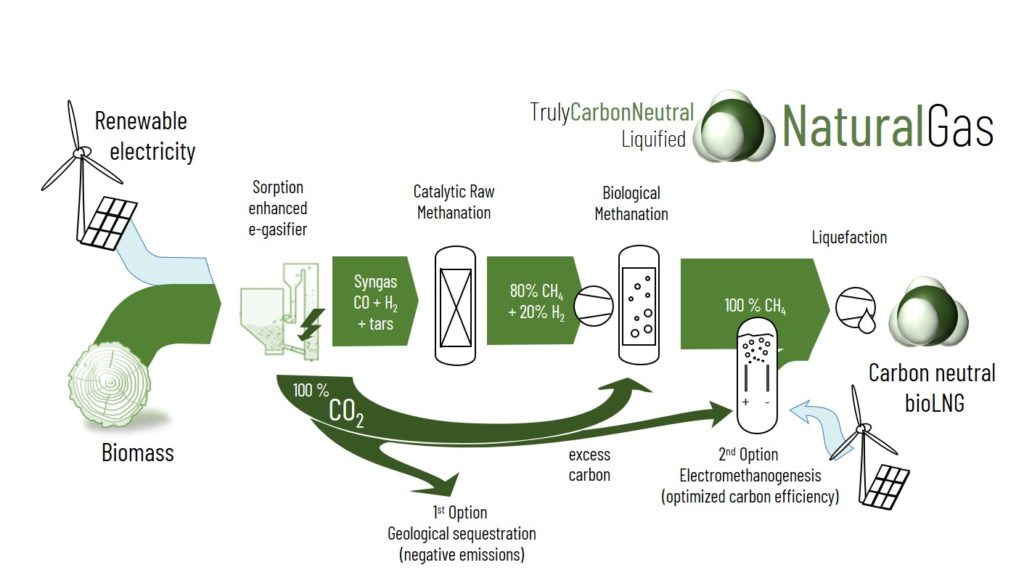

CarbonNeutralLNG targets the cost-competitive and carbon effective exploitation of carbon sources from biomass in order to replace fossil diesel fuels with renewable ‘electricity enhanced GreenLNG’ on a global scale. Low-carbon transportation will increasingly depend on liquid energy carriers like Liquefied Natural Gas from biomass (GreenLNG). Low-cost renewable energy (electricity and biomass) and reduced process complexity will be the main drivers for reduced marginal costs and increased carbon efficiency of the GreenLNG synthesis.

Support Code: 101084066

Term: 01.11.2022 – 31.10.2025

European Union

European Union

This project has received funding from Horizon Europe under Grant Agreement No 101084066.

National Technical University of Athens, Griechenland

University of Natural Resources and Life Sciences, Wien, Österreich

Electrochaea GmbH, Deutschland

Josef Bertsch Gesellschaft m.b.H & Co, Österreich

RINA-C Consulting SpA, Italien

University of Graz, Österreich

Ludwig-Maximilians-Universität München, Deutschland

BEST – Bioenergy and Sustainable Technologies GmbH, Österreich

Baltic Energy Innovation Centre, Schweden

The CarbonNeutralLNG project targets electricity enhanced conversion of biomass residues into CO/CO2 and subsequently into liquefied bio-methane (GreenLNG). The integration of renewable electricity maximizes the methane production from a certain amount of biomass resources by a factor of 2 and simplifies the conversion processes:

The project is funded by the EU on order to provide LNG for the transport sector, in particular for shipping or heavy-duty transport. In addition to this role as an “e-fuel” or advanced (electricity enhanced) biofuel, green LNG can also replace fossil natural gas for power generation, heat generation and in the chemical industry.

Contact:

Department of Chemical and Biological EngineeringJakob Müller, M. Sc.

Lehrstuhl für Energieverfahrenstechnik