EU-Project i³upgrade

EU-Project i³upgrade – Integrated and intelligent upgrade of carbon sources through hydrogen addition for the steel industry

EU-Project i³upgrade – Integrated and intelligent upgrade of carbon sources through hydrogen addition for the steel industry

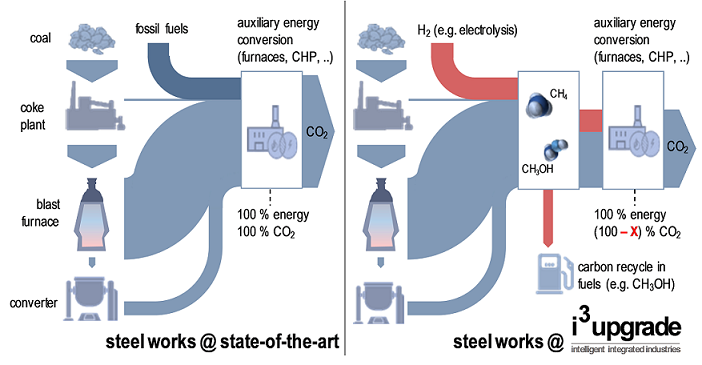

The project i3upgrade aims at the intelligent and integrated upgrade of carbon sources in steel industries through hydrogen intensified synthesis processes. In contrast to established synthesis processes, the project targets direct methanation and methanol synthesis of by-products in steel works under dynamic and transient conditions being operated by advanced control strategies. Agent-based modelling demonstrates the opportunities for reduction of CO2 emissions in steel works in the framework of emerging volatile markets. The final proof-of-concept of the new control strategies will be performed with real bottled steel mill gases as well as with a complex gas matrix from an existing gasifier.

Project Funding: This project has received funding from the Research Fund for Coal and Steel under grant agreement No 8006598.

Term: 01.06.2018 – 31.05.2022

i3upgrade aims at the intelligent and integrated upgrade of carbon sources in steel industries through hydrogen intensified synthesis processes and advanced process control technologies. The i3upgrade approach will in particula

- provide new flexible reactor concepts for the upgrade of coal-derived gases with varying composition and gas quality to methane and methanol

- optimize operation schemes by means of innovative advanced process control technologies

- enable CO2 savings through the integration of renewable hydrogen from volatile power sources

In accordance to TGC2 priority 1.3 “Innovative energy conversion cycles to increase revenue streams from coal power generation or steel industry while reducing carbon footprint” the consortium will apply these key innovations to an integrated steel works plant.

The upgraded carbonaceous streams partly substitute fossil fuels for the energy supply. In contrast to established synthesis processes, i3upgrade targets direct methanation and methanol synthesis of by-product gases in integrated steel works under transient conditions and with an addition of renewable hydrogen. Based on a detailed characterization of feasible operation windows, these syntheses will use advanced control strategies to address dynamic constraints of the integrated steelwork processes and of electricity grid services. Based on steel work process big-data analysis, the final proof-of-concept of the new control strategies will be done experimentally with bottled gases from the real converter and blast furnace plants as well as with a complex gas matrix from an existing coal gasifier.

Fig. 1: Flow diagram of an integrated steel works

Fig. 1: Flow diagram of an integrated steel works

Contact:

Department of Chemical and Biological EngineeringDr.-Ing. Peter Treiber

Lehrstuhl für Energieverfahrenstechnik