EnCN – project part 1.1: Base load storage systems with low-temperature storages

EnCN project part 1.1: Base load storage systems with low-temperature storages

Within the framework of the research project „Base load storage systems with low-temperature storages“ at energy campus Nuremberg a storage system is to be designed in order to buffer renewable excess electricity in a thermal storage.

Term: 01.01.2017 – 31.12.2021

![]()

Freistaat Bayern

Bayerisches Staatsministerium für Wirtschaft und Medien, Energie und Technologie

iPAT – Lehrstuhl für Prozessmaschinen und Anlagentechnik

Lehrstuhl für Technische Thermodynamik

Lehrstuhl für Thermische Verfahrenstechnik

Lehrstuhl Informatik 7 für Rechnernetze und Kommunikationssysteme

ZAE Bayern

Base load storage systems with low-temperature storages

To achieve the expansion targets of the Federal Government it is inevitable to use electricity which is generated on basis of solar power also at night, in order to provide baseload power. Systems which are capable of providing baseload power might substitute coal-based fossil generation with a high number of operating hours and thus maximize CO2 savings.

The research topic „Base load storage systems with low-temperature storages“ is processed within the subprojects SP1-1 „Upgrading of low-temperature heat with reversible HP-ORC-systems“ and SP1-2 „Large low-temperature storages which are designed for temperatures up to 150 °C“, which are subordinated to the project Speicher A of EnCN.

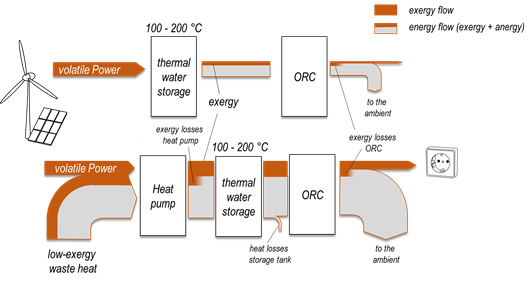

Both subprojects deal with the implementation of a reversible heat pump/ORC process in combination with a large low-temperature storage. Excess power, generated by wind turbines or photovoltaic systems, is to be used to upgrade geothermal heat or industrial waste heat by means of a heat pump. Heat pumps enable a significant higher temperature level than classical immersion heaters by using the same amount of electricity. To reduce investment costs a bulk of components of the heat pump are used as ORC process for the purpose of reconversion to electricity.

In this project the Chair of Energy Process Engineering deals with a technical and economical feasibility analysis for the model region Wunsiedel. Based on market analyses the most promising suppliers and technologies for implementing a demonstration project in the framework of a feasibility analysis are to be found for power ranges between 100 kW and 10 MW.

Contact:

Department of Chemical and Biological EngineeringMaximilian Weitzer, M. Sc.

Lehrstuhl für Energieverfahrenstechnik