Ash melting behavior

Ash melting behavior in biomass-fuelled fluidised beds

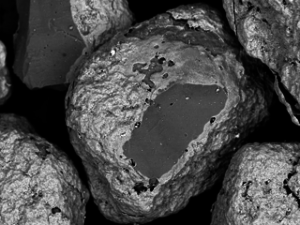

Fluidised bed combustion is predestined for the use of biofuels. Low ash melting temperatures, however, often result in operational problems and plant damage in commercial facilities. The main reason for this is the composition of the biomass and to be more precise the high contents of alkalis and chlorine. These cause low ash melting points and are thus responsible for the formation of agglomerates which subsequently lead to the defluidisation of the fluidised bed. Costly repairs and lengthy plant shutdowns are the result.

The focus of EVT’s research lies on the development of appropriate measurement methods to predict and prevent these problems in order to extend the range of use of biofuels. The aim is to develop and test new, innovative concepts by systematically examining emerging phenomena.

Contact:

Steffen Leimbach, M. Sc.

Department of Chemical and Biological Engineering

Lehrstuhl für Energieverfahrenstechnik

- Phone number: 09115302-99059

- Email: steffen.leimbach@fau.de