Hydrogen from biomass

BHC: Hydrogen from biomass

The BHC (Bavarian Hydrogen Center) is a cooperation project between FAU and other research facilities. In this research project, the involved scientists are searching for possibilities to extract and use hydrogen obtained exclusively from regenerative sources. In addition, the researchers want to promote the systematic expansion of chemical energy storage using hydrogen.

Subproject I.1.1 – Hydrogen from biomass

Term: 01.05.2012 – 30.09.2016

![]()

Bayerische Staatsregierung

- Friedrich-Alexander-Universität Erlangen-Nürnberg

LS für Chemische Reaktionstechnik (Prof. Wasserscheid, Prof. Schwieger)

LS für Thermische Verfahrenstechnik (Prof. Arlt, Prof. Kaspereit)

LS für Technische Thermodynamik (Prof. Wensing)

LS für Prozessmaschinen und Anlagentechnik (Prof. Schlücker)

Erlangen Catalysis Resource Center (Prof. Hartmann)

- Technische Universität München

LS für Thermodynamik (Prof. Sattelmayer)

- Universität Bayreuth

Zentrum für Energietechnik (ZET) (Prof. Brüggemann)

- Hochschule Amberg-Weiden

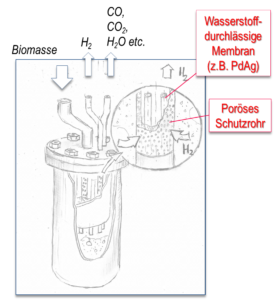

The Heatpipe-Reformer for the gasification of biomass, developed at the Technical University of Munich by Prof. Karl, is ideally suitable to produce hydrogen in the chemical industry due to high hydrogen contents. One problem, however, is the complicated down-stream process for obtaining the hydrogen in pure form. Therefore, hydrogen is separated directly through metal membranes (e.g. palladium) in the fluidised bed in the reformer. The sketch shows the schematic structure of the heat pipe reformer for hydrogen separation.

Removing the hydrogen from the reaction system shifts the equilibrium of the water gas reaction in favour to a higher hydrogen yield. The photo shows Jonas Leimert working on the permeation test bench:

To implement this method several work packages are to be carried out at the Chair of Energy Process Engineering:

- Testing of membranes in synthesis gas mixtures and fluidised bed layers

- Construction of the heat pipes for the reformer

- Construction of the Heatpipe Reformer with integrated hydrogen separation

Contact:

Prof. Dr.-Ing. Jürgen Karl

Department of Chemical and Biological Engineering

Lehrstuhl für Energieverfahrenstechnik

- Phone number: 09115302-99021

- Email: juergen.karl@fau.de