DFG-Project: KoksAgglomeration

DFG-Project: KoksAgglomeration – Bed agglomeration in bubbling fluidized beds during gasification of low-rank biomass feedstock

Basic research towards improved bed agglomeration detection techniques and a mechanistic understanding of agglomeration mechanisms during fluidized bed gasification at elevated shares of residual carbon.

Projectnumber: 389368186

Term: 12.2017 – 02.2022

Over the last years, the investigation and detection of bed agglomeration in fluidized bed combustion has been one of EVT’s foci.

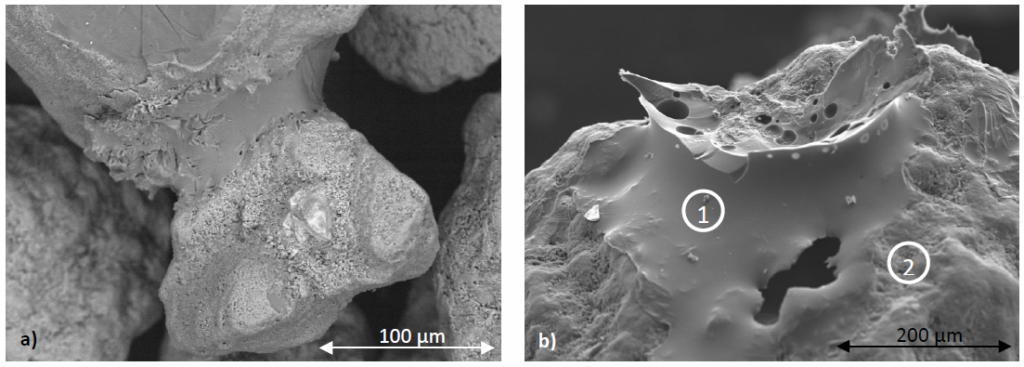

The research project “KoksAgglomeration”, funded by the Deutsche Forschungsgemeinschaft (DFG) aims at the agglomeration tendency of solid biofuels during bubbling fluidized bed gasification. Special emphasis lies on the influence of residual carbon on agglomerate boundary layers.

The principle goals are

- the improvement of existing and development of new agglomeration detection techniques especially regarding the formation of initial particle coatings, based on high-frequent pressure analysis;

- the deduction of fuel and temperature-dependent agglomeration criteria. For this purpose, our project partner HI-ERN conducts Lattice-Boltzmann simulations of particle interactions (e.g. bed material collisions) with respect to environmental conditions, ash properties and residual carbon.

Eventually, this leads to a better understanding of the underlying effects and prevailing agglomeration mechanisms during fluidized bed gasification, potentially facilitating a transferable toolkit for the prediction of bed agglomeration in industrial plant setups.

Contact:

Department of Chemical and Biological EngineeringSteffen Leimbach, M. Sc.

Lehrstuhl für Energieverfahrenstechnik