EU-Project SolBio-Rev

EU-Project SolBio-Rev: Solar-Biomass Reversible energy system for covering a large share of energy needs in buildings

EU-Project SolBio-Rev: Solar-Biomass Reversible energy system for covering a large share of energy needs in buildings

The SolBio-Rev project will develop an innovative renewable energy system based on a novel and creative heat pump-based configuration, for the production of heating (space heating and domestic hot water), space cooling and electricity according to the daily and seasonal energy demand of buildings in different european climatic zones.

Term: 01.05.2019 – 30.04.2023

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 814945

Project website

Project partners

National Technical University of Athens

Consiglio Nazionale Delle Ricerche

Universidad De Lleida

Karlsruher Institut für Technologie

Universita Degli Studi Di Messina

University of Sussex

Fahrenheit GmbH

T.E.A.V.E Ltd

![]()

AkoTec Produktionsgesellschaft mbH

![]()

DAIKIN Airconditioning Hellas SA

DBC Europe SA

Techlink

ÖkoFEN Forschungs- und Entwicklungs GmbH

![]()

Strabag Belgium SA

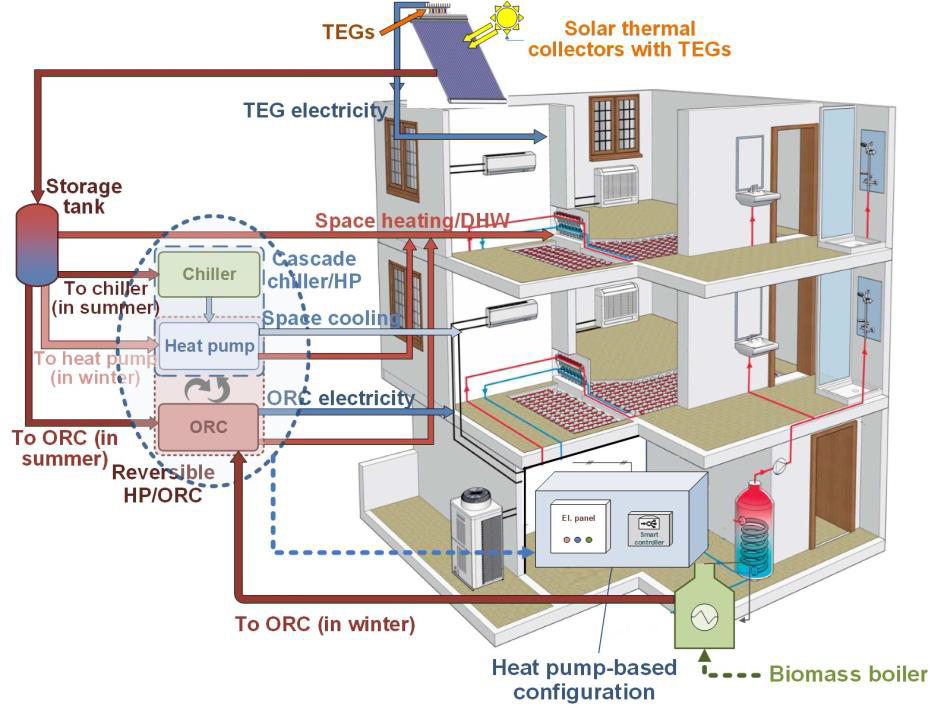

The SolBio-Rev concept relies on integrating a creative heat pump-based configuration with innovative components and an advanced system control that combined allow the maximised use of renewable energy in buildings at any moment of the year in all EU climatic zones. This configuration consists of a reversible heat pump/Organic Rankine Cycle (ORC) coupled with a cascade chiller with a heat pump, as shown in Fig. 1. These two components share the same heat pump, in order to attain enhanced flexibility and compactness.

Heat is supplied to this configuration primarily by vacuum tube solar thermal collectors equipped with thermoelectric generators (TEGs) for additional electricity production by maximising the utilisation of excess, otherwise wasted, solar heat and avoiding overheating. The heat utilised by TEGs does not have any impact on the operation of the other components (e.g. ORC, chiller), operating in a supplemental fashion. The heating needs not covered by solar thermal energy or the heat pump during winter are provided by the backup heater: a biomass boiler operating at combined heat and power (CHP) mode with low air pollutants, supplying high-temperature heat to the same ORC, and using the ORC rejected heat for space heating, reaching a high cogeneration efficiency.

The targeted benefit of the SolBio-Rev that combines different renewable energy systems is to reach an energy share of 70 – 85 % in a variety of EU buildings, with a modular, flexible and compact energy system. The overall goal is to validate this new technology in an intended environment. The research work aims at the development and integration of the system components along with a smart system control. At the same time the air pollutant emissions and the dependency on fossil fuels will be reduced.

The key advantages of the SolBio-Rev system are:

- High flexibility for producing heating, cooling and electricity according to the energy needs

- Reduction of equipment due to synergistic operation of the heat pump-based configuration

- Applicability in a variety of buildings all over Europe

- Low costs due to the innovative features, high compactness, and advanced system integration

Two prototype systems will be developed and tested for one year in Greece and in Germany, for reaching an energy share of at least 70 % and thus validate the SolBio-Rev concept.

Contact:

Department of Chemical and Biological EngineeringMaximilian Weitzer, M. Sc.

Lehrstuhl für Energieverfahrenstechnik