BMWi-project: ANICA – Advanced Indirectly Heated Carbonate Looping Process

The BMWi-project ANICA continues the research work of the previous project CARINA. The Carbonate Looping Process is examined to reduce CO2 in coal-fired power plants and will be optimized for better efficiency.

Project: 294766

Term: 01.09.2019 – 31.08.2022

ACT programme (Accelerating CCS Technologies, Horizon2020)

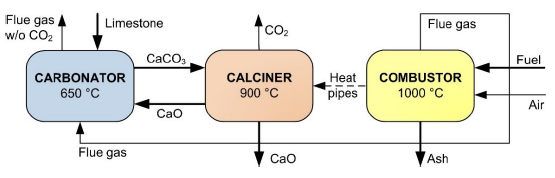

Due to the energy transition, it is necessary to establish new and develop existing methods to capture CO2. The carbonate looping process is a promising method to reduce CO2. In the carbonator, CO2 resulting from exhaust gases gets exothermically absorbed by CaO at temperatures of about 650 ° C and reacts to CaCO3. Through heat consumption in the calciner, the reverse reaction occurs at temperatures of approx. 900°C degrees. The purified CO2 gets captured and stored and CaO is reused to capture CO2 of flue gases.

The required heat for the calciner is indirectly provided through heat pipes, which eliminates the energy-consuming process of oxygen filtration.

Within the framework of the project „CARINA” (Carbon Capture by means of an Indirectly heated Carbonate Looping Process), the carbonate looping process was tested for the CO2 reduction in power plants and optimised in terms of its efficiency.

The current project called “ANICA” (Advanced Indirectly Heated Carbonate Looping Process) is adapting this method to the lime and cement industry by applying optimized concepts.

Contact:

Department of Chemical and Biological EngineeringKyra Böge, M. Sc.

Lehrstuhl für Energieverfahrenstechnik