Process heat generation from biogenic solid fuels using oxyfuel gasification and gas conditioning for optimised use in industrial burner systems

The aim of the BioProcessHeat project is to develop and demonstrate a process for the CO₂-neutral generation of high-temperature process heat by combining biomass oxyfuel gasification and catalytic gas conditioning. The aim is to demonstrate that fossil natural gas can be replaced economically and technically by biogenic synthesis gases in industrial combustion processes, e.g. in the ceramics, metal or building materials industries.

Support Code: 03EI5478A

Duration: : 01.12.2024 – 30.11.2027

Around 72% of industrial process heat in Germany is still generated using fossil fuels. Decarbonisation in this area is therefore essential for achieving the German government’s climate targets.

Although electricity-based process heat generation is on the rise, there are numerous industrial applications that still require gaseous fuels due to the nature of the processes involved. Hydrogen is considered a promising energy source, the availability of which is set to increase in the future through electrolysis. However, it can be assumed that large consumers in the steel, cement and chemical industries in particular will account for the majority of marketable hydrogen. Combined with a pipeline infrastructure that is initially only available in certain areas, this will result in bottlenecks and high costs for widespread decentralised use.

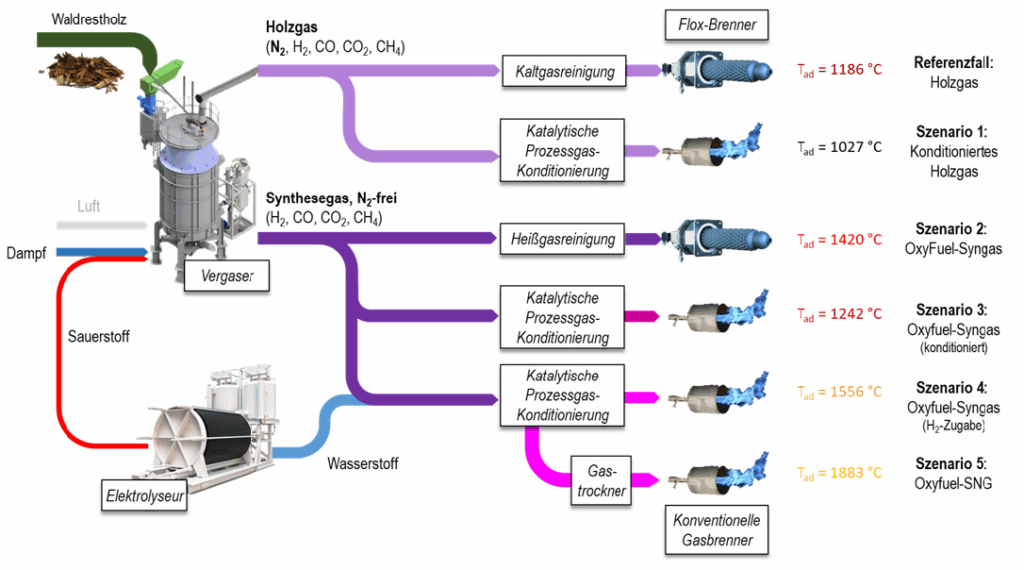

A realistic alternative is the gasification of biomass to produce combustible synthesis gases. These can be conditioned for specific processes and adapted to existing burner technologies. This opens up a path to CO2-neutral process heat generation even for temperature ranges from 1000 to 1800 °C.

Figure 1: Sketch of possible process paths (depending on application and required flame temperature)

In order to motivate industry to realise the production of CO2-neutral high-temperature process heat, various process chains for heat generation are to be field-tested and demonstrated in the project (see Figure 1). The central activity of the project is therefore the construction and commissioning of a pilot plant. An innovative counterflow gasifier will be operated there, enabling both air- and oxygen-fuelled (oxyfuel) modes of operation. One focus is on testing oxyfuel gasification under real conditions and characterising the synthesis gases produced. In the future, the process chain is to be expanded to include a methanation plant and an industrial burner. The test campaigns serve to systematically investigate different operating modes, in particular in comparison to conventional air gasification.

Contact: