BHC: load-flexible high-temperature electrolysis

BHC (Bavarian Hydrogen Center) is a joint venture between several research institutions. It aims to find possibilities of gain and use hydrogen out of renewable sources. The second aspect of the research is to push further the development of chemical storage for hydrogen.

Part of project I.2.1 – load-flexible high-temperature electrolysis

Term: 01.05.2012 – 30.06.2015

Bayerische Staatsregierung

- Friedrich-Alexander-Universität Erlangen-Nürnberg

LS für Chemische Reaktionstechnik (Prof. Wasserscheid, Prof. Schwieger)

LS für Thermische Verfahrenstechnik (Prof. Arlt, Prof. Kaspereit)

LS für Technische Thermodynamik (Prof. Wensing)

LS für Prozessmaschinen und Anlagentechnik (Prof. Schlücker)

Erlangen Catalysis Resource Center (Prof. Hartmann)

- Technische Universität München

LS für Thermodynamik (Prof. Sattelmayer)

- Universität Bayreuth

Zentrum für Energietechnik (ZET) (Prof. Brüggemann)

- Hochschule Amberg-Weiden

Increasing volatility in electricity production from renewable sources requires large storage capacities, in storage power as well as in size, with transient and alternating operation capabilities. Targeting the potential of chemical energy storage systems based on hydrogen, water electrolysis is one of the most common entry steps to this technology path.

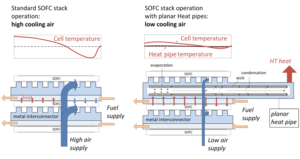

High temperature solid oxide cells, operated alternately in electrolyser or fuel cell mode, represent an appealing approach for efficient electricity storage via hydrogen production / consumption. The work at EVT analyses the thermal balance of solid oxide electrolyser cell / fuel cell systems in order to enable highly transient operation at high temperatures and high storage efficiencies.

|

|

|

|

Contact Person:

Dr.-Ing. Peter Treiber

Department of Chemical and Biological Engineering

Lehrstuhl für Energieverfahrenstechnik

- Phone number: 09115302-99035

- Email: peter.treiber@fau.de