SustainableGas

BMWi-Project: SustainableGas – Scenarios for the development of renewable gases for the heat and electricity market

The BMWi-Project SustainableGas simulates different process chains of the substitution of natural gas by the use of renewable energies. Economical and ecological feasibility is taken into account, as well as its social acceptance.

Support Code: 03ET4033A

Term: 01.06.2016 – 30.11.2018

Partners

Department für Geographie der Ludwig-Maximilians-Universität München

Lst. für Kommunikationswissenschaft der FAU Erlangen-Nürnberg

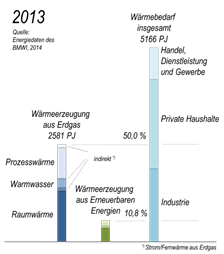

The Federal Republic of Germany’s heat supply is currently based on the use of fossil natural gas by approximately 50%. Renewable energy’s contribution in heat supply is not more than 11%. In order to achieve climate protection goals, a fast transformation of the heat market towards high portions of renewable energies is inevitable. Furthermore, a structural change of gas supply is essential to guarantee price stability and supply security in the long term for the gas-based heat supply.

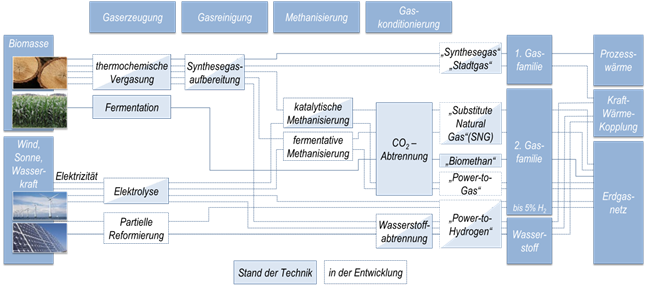

To cope with the insecurities of conventional natural gas supply, there’s a multitude of technical developments aiming towards the generation of natural gas substitutes from renewable resources:

- “Biomethane” by the treatment of biogas to achieve a natural-gas-like quality

- Generation of natural gas by methanisation of synthesis gas gained from thermochemical conversion of ligneous biomass (“Substitute Natural Gas”)

- Regenerative generation of hydrogen (“Power-to-Hydrogen”) and its conversion to synthetic natural gas (“Power-to-gas”)

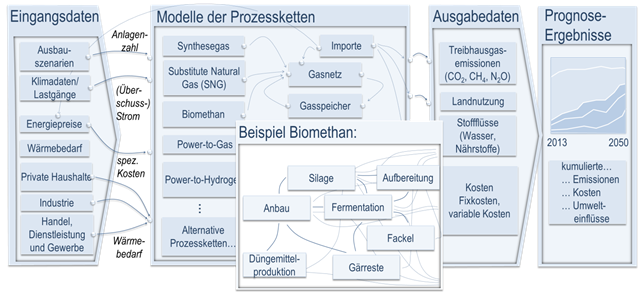

In cooperation with the chair for communication studies of the FAU Erlangen-Nuremberg and the department of geology of the LMU Munich, possible strategies for an environmentally friendly use of renewable energies for the substitution of natural gas for the heat and electricity market are developed. The aim is to evaluate currently published process chains comprehensively and interdisciplinary regarding

- their Potentials and costs,

- their ecological assessment as well as

- their acceptance within society and the energy sector.

The basis of the evaluation of the process chains is an agent-based simulation of different expansion scenarios up to the year 2050. The agent-based and dynamic modeling allows to take back couplings between the individual agents on different system levels into account.

Contact:

Dr.-Ing. Sebastian Kolb

Department of Chemical and Biological Engineering

Lehrstuhl für Energieverfahrenstechnik

- Phone number: 09115302-99028

- Email: sebastian.kolb@fau.de